Overview

Choosing the right excavator for earthmoving projects is crucial for ensuring the success and efficiency of any construction or landscaping task. The right excavator can significantly enhance productivity by enabling faster and more precise work, reducing the time and effort required to complete a project. Additionally, using the appropriate excavator improves efficiency by matching the machine’s capabilities to the specific requirements of the job, thereby optimizing fuel consumption and minimizing wear and tear.

Safety is another paramount concern on any job site. An excavator that is well-suited to the task at hand reduces the risk of accidents and equipment failures. Properly sized and equipped excavators provide better stability and control, allowing operators to work more confidently and safely in various conditions. Whether you are digging foundations, clearing land, or handling heavy materials, selecting the right excavator is key to achieving high-quality results while maintaining a safe and efficient work environment.

Assessing Your Project Needs

1.1 Understanding the Scope of Work

The type and scale of your project play a significant role in determining the right excavator for the job. For small-scale residential projects, such as backyard landscaping or minor utility work, a mini excavator may be sufficient. These machines are compact, maneuverable, and ideal for working in tight spaces. On the other hand, large-scale construction projects, such as commercial building foundations or major roadworks, require standard or large excavators that offer more power and reach.

Understanding the specific tasks your project entails is equally important. Different tasks, such as digging trenches, lifting heavy materials, demolition, or grading, demand different capabilities from an excavator. For instance, demolition tasks require machines with robust hydraulic systems and specialized attachments, while trenching might prioritize depth and precision. By clearly defining the scope and specific tasks of your project, you can better match the excavator’s features and capabilities to your needs, ensuring optimal performance and efficiency.

1.2 Identifying the Terrain and Site Conditions

The terrain and site conditions of your project area significantly affect excavator performance and should be carefully considered when choosing the right machine. Different terrains, such as rocky, sandy, or clay-rich soils, present unique challenges. For example, rocky terrain requires an excavator with strong digging force and durable attachments, while sandy soil might necessitate wide tracks to prevent sinking and improve stability.

Working on slopes or uneven ground adds another layer of complexity. Excavators with excellent stability and traction are essential for maintaining safety and efficiency on inclined surfaces. Additionally, muddy or wet conditions can hinder machine movement and operation, making it important to choose an excavator with features like high ground clearance and powerful traction systems.

Confined spaces also impact excavator choice. In urban environments or areas with limited access, a compact or zero-tail-swing excavator can maneuver more easily without causing damage to surrounding structures. By thoroughly assessing the terrain and site conditions, you can select an excavator that not only meets the demands of your project but also ensures safe and efficient operation throughout the work.

Types of Excavators

2.1 Mini Excavators

Mini excavators are compact, lightweight machines ideal for small to medium projects. Their small size makes them highly maneuverable, allowing them to navigate through tight spaces and work efficiently in confined areas, such as residential backyards or urban construction sites. Mini excavators are perfect for tasks that require precision and delicacy, such as trenching, landscaping, and minor demolition work. Their ability to access areas that larger machines cannot reach makes them indispensable for projects with space constraints.

2.2 Standard Excavators

Standard excavators are the most versatile and commonly used type of excavator, suitable for a wide range of medium to large projects. They offer a balanced combination of power, size, and reach, making them capable of handling various tasks, including digging, lifting, grading, and material handling. Standard excavators can be equipped with a variety of attachments, further enhancing their versatility. Their moderate size allows them to operate efficiently on larger construction sites without compromising on maneuverability. These machines strike a perfect balance between performance and practicality, making them a popular choice for many contractors.

2.3 Large Excavators

Large excavators are designed for major construction projects that require substantial power and reach. These machines are equipped with powerful engines and robust hydraulic systems, enabling them to handle heavy-duty tasks such as large-scale excavation, mining, and major demolition projects. Their extended reach and deep digging capabilities allow them to move large volumes of material quickly and efficiently. While their size may limit maneuverability in confined spaces, their unmatched power and productivity make them essential for large-scale operations. Large excavators are built to withstand rigorous working conditions and deliver high performance in demanding environments.

2.4 Specialty Excavators

Specialty excavators are designed for specific tasks and unique project requirements. Examples include:

Long-Reach Excavators: These machines have extended booms and arms, allowing them to reach farther than standard excavators. They are ideal for dredging, deep excavation, and working over water or other obstacles.

Amphibious Excavators: Equipped with floating pontoons and waterproof components, amphibious excavators are perfect for working in wetlands, swamps, and other waterlogged areas. They can perform dredging, reclamation, and environmental cleanup tasks that conventional excavators cannot.

Vacuum Excavators: These machines use high-powered suction to remove soil and debris without damaging underground utilities. They are ideal for utility installation, repair work, and sensitive excavation tasks.

Specialty excavators are most effective in scenarios where standard machines would struggle or fail to deliver the required performance. By selecting the appropriate specialized excavator for your project, you can achieve optimal results and efficiency in challenging or unique environments.

Key Specifications to Consider

3.1 Operating Weight

Choosing an excavator with the right operating weight is crucial for ensuring stability and optimal performance. The operating weight affects the machine’s ability to remain stable while lifting and moving materials. An excavator that is too light may struggle with heavy loads, risking tipping or loss of control, while an overly heavy machine might cause unnecessary soil compaction and damage to the job site. Matching the excavator’s weight to the project’s requirements ensures safe and efficient operation, particularly on uneven or unstable terrain.

3.2 Engine Power

Engine power is a critical factor that influences an excavator’s capabilities and overall efficiency. A powerful engine provides the necessary force to perform demanding tasks such as deep digging, heavy lifting, and fast material movement. It also impacts the machine’s ability to work continuously without overheating or experiencing performance drops. When selecting an excavator, consider the power requirements of your project. Higher engine power translates to greater productivity and the ability to handle more challenging jobs, making it essential for larger or more intensive projects.

3.3 Bucket Capacity

The bucket capacity of an excavator determines how much material can be moved in a single scoop, directly affecting the efficiency of material handling and excavation tasks. A larger bucket capacity allows for quicker completion of tasks that involve moving large volumes of material, such as earthmoving or loading trucks. However, it’s important to balance bucket size with the machine’s stability and power. Overloading an excavator can lead to operational inefficiencies and increased wear and tear. Choosing the appropriate bucket capacity for your project’s needs ensures efficient material handling and prolongs the equipment’s lifespan.

3.4 Reach and Dig Depth

Reach and dig depth are key specifications that determine an excavator’s ability to perform specific tasks. Reach refers to how far the excavator arm can extend, which is important for tasks such as digging trenches or working across obstacles. Dig depth indicates how deep the excavator can dig below the ground surface. Both specifications are vital for matching the excavator to the project requirements. For example, deep excavation projects or tasks that require reaching over barriers will benefit from an excavator with extended reach and greater dig depth capabilities. Ensuring the excavator meets these specifications helps achieve project goals efficiently.

3.5 Hydraulic Systems

The hydraulic system is the heart of an excavator, powering its various functions, including arm movement, bucket operation, and attachment control. High-quality hydraulic systems enhance the machine’s performance, enabling smooth and precise operations. Advanced hydraulic systems offer better control, faster cycle times, and the ability to handle a variety of attachments, increasing the excavator’s versatility. When choosing an excavator, evaluate the hydraulic system’s capacity and compatibility with the tasks you intend to perform. A robust hydraulic system ensures the excavator operates efficiently and can adapt to different job site demands.

By considering these key specifications, you can select an excavator that not only meets the demands of your earthmoving project but also provides reliable, efficient, and safe performance.

Attachments and Accessories

4.1 Common Attachments

Attachments play a crucial role in extending the functionality and versatility of an excavator. Here are some common attachments and how they enhance the excavator’s capabilities:

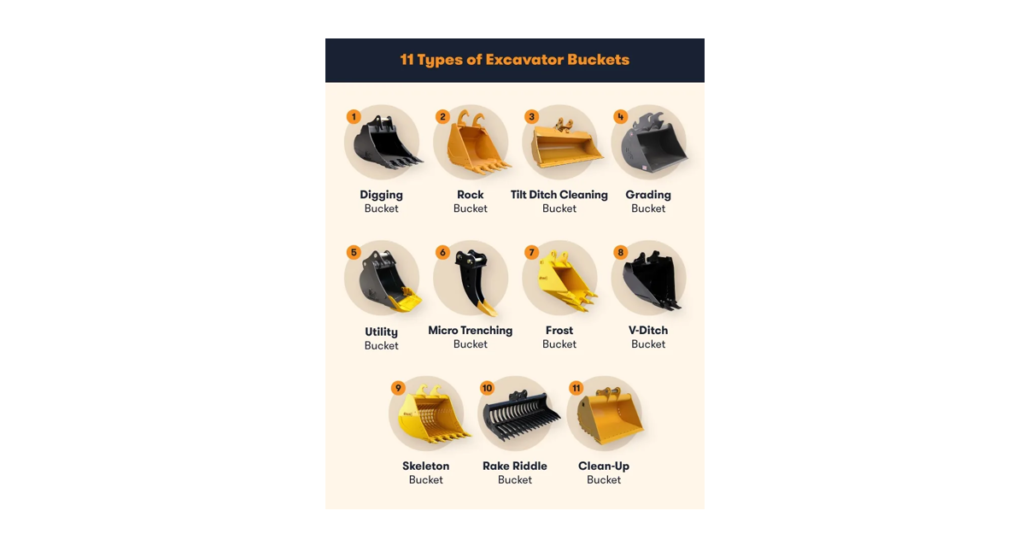

Buckets: The most common attachment, available in various sizes and types, such as digging buckets, grading buckets, and trenching buckets. Each type is designed for specific tasks, like digging, scooping, and leveling.

Breakers: Also known as hydraulic hammers, breakers are used for demolishing concrete, rock, and other hard materials. They are essential for construction and demolition projects that require breaking down tough surfaces.

Grapples: These are ideal for handling bulky or irregularly shaped materials such as logs, rocks, and scrap metal. Grapples are commonly used in forestry, recycling, and demolition applications.

Augers: Used for drilling holes in the ground, augers are perfect for projects that require fence post installation, tree planting, or foundation work. They come in various sizes to match the diameter and depth requirements of the holes.

By utilizing the appropriate attachments, an excavator can perform a wide range of tasks beyond simple digging, making it a highly versatile piece of equipment suitable for various project needs.

4.2 Quick Couplers

Quick couplers are devices that allow for rapid and easy attachment changes without the need for manual tools. Here are some advantages of using quick couplers:

Time Efficiency: Quick couplers significantly reduce the time required to switch between different attachments, enhancing overall productivity. This is especially beneficial in projects where multiple tasks need to be performed consecutively.

Operator Convenience: With quick couplers, operators can change attachments from the cab without leaving the controls. This not only saves time but also reduces physical strain and increases safety.

Versatility: Quick couplers make it easy to switch between a wide range of attachments, allowing one excavator to perform multiple functions on the job site. This versatility can reduce the need for additional machines, saving costs and space.

Improved Workflow: The ability to quickly adapt to different tasks ensures a smoother workflow and minimizes downtime, helping to keep projects on schedule.

Quick couplers are a valuable addition to any excavator, enhancing its adaptability and efficiency. They are especially useful in dynamic job environments where the ability to quickly switch between tasks is essential for maintaining productivity.

By considering the right attachments and utilizing quick couplers, you can maximize the functionality and efficiency of your excavator, making it a more versatile and valuable asset on any earthmoving project.

Evaluating Manufacturer and Dealer Support

5.1 Brand Reputation

When choosing an excavator for earthmoving work, the reputation of the manufacturer is a critical factor to consider. Here’s why:

Reliability: Reputable brands are known for producing reliable machinery that can withstand the demands of tough job sites. Choosing a well-regarded brand reduces the risk of unexpected breakdowns and costly repairs.

Durability: High-quality manufacturers use superior materials and engineering practices, ensuring their machines have a longer lifespan. This durability translates to better long-term value for your investment.

Innovation: Established brands often lead in technological advancements, incorporating innovative features that enhance performance, safety, and efficiency. Access to the latest technology can provide a competitive edge in completing projects more effectively.

Resale Value: Equipment from reputable brands generally holds its value better over time. If you plan to sell or trade in your excavator in the future, a well-known brand can yield a higher resale value.

Choosing a trusted brand ensures you are investing in a machine that is built to perform reliably under various conditions, providing peace of mind and consistent performance.

5.2 Dealer Support

Strong dealer support is another crucial aspect of selecting the right excavator. Here’s why it matters:

Parts Availability: Access to genuine parts is essential for maintaining and repairing your excavator. A reliable dealer network ensures that replacement parts are readily available, minimizing downtime and keeping your project on track.

Service Options: Authorized dealers offer professional service and maintenance, often with technicians trained specifically for the brand’s equipment. This expertise ensures that your machine is serviced correctly, enhancing its performance and lifespan.

Warranty Support: Purchasing from an authorized dealer often includes warranty support, providing coverage for repairs and replacements within a specified period. This can significantly reduce unexpected expenses related to equipment failure.

Training and Resources: Many dealers provide training for operators and maintenance staff, ensuring that your team can operate and maintain the excavator safely and efficiently. Additionally, access to resources like user manuals and troubleshooting guides can be invaluable.

Customer Service: Good dealers offer excellent customer service, assisting with everything from selecting the right machine to ongoing support and troubleshooting. This partnership can be crucial for addressing any issues quickly and effectively.

By choosing a manufacturer with a strong reputation and ensuring robust dealer support, you can enhance the overall ownership experience, ensuring your excavator remains a reliable and productive asset for your earthmoving projects.

Considering both the reputation of the brand and the quality of dealer support helps ensure that you select an excavator that meets your needs and can be maintained effectively, providing long-term value and reliable performance on the job site.

Renting vs. Buying

6.1 Renting

Renting an excavator can be a cost-effective and practical option in various situations. Here are some scenarios where renting might be more advantageous:

Short-Term Projects: For projects that are temporary or have a defined short duration, renting an excavator can be more economical. It eliminates the need for a large upfront investment and reduces long-term financial commitments.

Specialized Equipment Needs: If your project requires a specific type of excavator or attachment that you don’t use frequently, renting allows you to access the equipment without purchasing it. This is particularly useful for unique tasks that require specialized machinery.

Testing New Models: Renting provides an opportunity to test different models and brands before making a purchase decision. This can help you determine which excavator best meets your needs in terms of performance, features, and comfort.

Maintenance and Repairs: Rental companies typically handle maintenance and repairs, reducing your operational burden. This ensures that the equipment is always in good working condition and minimizes downtime on your project.

Budget Constraints: For businesses with limited capital or those looking to manage cash flow more effectively, renting can be a more feasible option. It allows you to allocate funds to other critical areas of your project or business operations.

Renting offers flexibility and convenience, making it an ideal choice for specific projects or situations where long-term ownership is not necessary.

6.2 Buying

Purchasing an excavator can be advantageous for long-term projects or frequent use. Here are the benefits of buying an excavator:

Long-Term Cost Savings: While the initial investment is higher, owning an excavator can be more cost-effective in the long run, especially if you have ongoing or frequent projects. You avoid the continuous rental fees and have full control over the equipment.

Availability: Owning your excavator means it’s always available when you need it. There’s no need to coordinate with rental schedules or worry about equipment availability, allowing for greater project flexibility and efficiency.

Customization: Ownership allows you to customize the excavator to better suit your specific needs. You can equip it with the attachments and features that are most beneficial for your projects, optimizing performance and productivity.

Asset Value: An excavator is a tangible asset that can contribute to the overall value of your business. Well-maintained equipment can also have good resale value, providing a return on your investment if you decide to sell it in the future.

Operational Control: Owning the equipment gives you full control over its use, maintenance schedule, and condition. This ensures that the excavator is always ready for your projects and can be maintained according to your standards.

Tax Benefits: Depending on your location and business structure, purchasing equipment can provide tax advantages. Depreciation and other deductions related to equipment ownership can reduce your taxable income.

Buying an excavator is a strategic decision for businesses with long-term or frequent equipment needs, offering greater control, customization, and potential cost savings over time.

By weighing the pros and cons of renting versus buying, you can make an informed decision that aligns with your project requirements, financial situation, and long-term business goals. Whether renting or buying, selecting the right excavator will significantly impact the success and efficiency of your earthmoving work.

Practical Tips for Making the Final Decision

7.1 Test Drive

Before making a final decision, arranging a test drive of the excavator is crucial. Here’s why:

Comfort and Ergonomics: Operating an excavator can be physically demanding, so it’s essential to ensure the machine is comfortable for the operator. A test drive allows you to assess the ergonomics of the cab, the comfort of the seat, and the ease of accessing controls.

Ease of Operation: Different excavator models can have varying control layouts and operational nuances. Testing the machine lets you evaluate how intuitive and responsive the controls are, ensuring that the operator can handle the excavator efficiently and safely.

Performance Check: A test drive provides an opportunity to check the machine’s performance under real working conditions. You can observe how it handles tasks such as digging, lifting, and maneuvering, which helps in determining if it meets your project requirements.

Identifying Issues: For used excavators, a test drive can reveal any potential issues that might not be apparent in a visual inspection. Listen for unusual noises, check for smooth operation, and ensure all features and attachments are functioning correctly.

7.2 Reviewing Maintenance Records

For used excavators, reviewing maintenance records is an essential step in the decision-making process:

Condition Verification: Maintenance records provide a detailed history of the machine’s upkeep, including routine maintenance and major repairs. This information helps verify the current condition of the excavator and identify any potential red flags.

Service History: Consistent and thorough service history indicates that the previous owner took good care of the equipment. Look for records of regular oil changes, filter replacements, hydraulic system checks, and other routine maintenance tasks.

Major Repairs and Replacements: Check for any major repairs or parts replacements in the service records. Understanding the nature and frequency of these repairs can give you insights into the machine’s reliability and potential future issues.

Authorized Service Providers: Maintenance performed by authorized or reputable service providers is usually more reliable. Verify the credibility of the service providers listed in the records to ensure that the maintenance work was carried out to high standards.

7.3 Considering Total Cost of Ownership

When choosing an excavator, it’s important to consider the total cost of ownership (TCO) beyond the initial purchase price:

Maintenance Costs: Regular maintenance is crucial to keep the excavator in good working condition. Estimate the ongoing maintenance costs, including parts, labor, and routine service intervals, to get a clear picture of the long-term expenses.

Fuel Efficiency: Fuel costs can be a significant part of the operating expenses. Evaluate the excavator’s fuel efficiency and estimate the fuel consumption based on your projected usage to understand the impact on your budget.

Insurance Costs: Insuring the excavator is necessary to protect your investment. Check the insurance premiums for different models and consider how factors like the machine’s value, age, and usage affect the insurance costs.

Depreciation: Factor in the depreciation rate of the excavator over time. Understanding how quickly the machine’s value will decrease helps in planning for future upgrades or replacements.

Resale Value: Consider the potential resale value of the excavator when it’s time to sell or trade it in. Machines from reputable brands with well-documented service records tend to have higher resale values, providing better returns on your investment.

By considering these practical tips, you can make a well-informed decision when choosing the right excavator for your earthmoving work. Taking the time to test drive the machine, review maintenance records, and evaluate the total cost of ownership ensures that you select an excavator that meets your needs, fits your budget, and delivers reliable performance.

Conclusion

Choosing the right excavator for your earthmoving needs is crucial to ensuring efficiency, productivity, and safety on the job site. By assessing your project requirements, understanding the types of excavators available, and considering key specifications and attachments, you can make an informed decision that best suits your needs. Additionally, evaluating manufacturer and dealer support, as well as weighing the benefits of renting versus buying, will help you select the most suitable excavator for your projects. Taking the time to review maintenance records and considering the total cost of ownership will further ensure that your investment is sound and reliable.

We invite you to explore our extensive inventory of excavators and discover the perfect match for your earthmoving projects. For personalized assistance and expert advice on selecting the right equipment, please visit our website www.holightgroup.com, or contact us at sales@holightgroup.com directly. Let us help you find the excavator that will enhance your productivity and ensure the success of your projects.