Excavators are essential pieces of machinery in the construction and engineering industries. They come in various sizes and types, each suited to different tasks and project requirements. Among the many types, mini and small excavators are particularly notable for their versatility and efficiency in a range of applications. This article delves into a comparative analysis of mini and small excavators, focusing on their core differences, performance, cost considerations, suitability for various tasks, and maintenance needs, specifically in the context of second-hand branded products.

Understanding the Core Differences

Mini and small excavators, while similar in many aspects, have several distinct differences that make them suitable for specific types of work. The primary difference lies in their size and weight. Mini excavators typically weigh between 1 to 5 tons, making them lightweight and highly maneuverable. In contrast, small excavators usually range from 5 to 10 tons, providing a balance between power and compactness.

Mini excavators are designed for precision tasks in confined spaces, such as residential construction, landscaping, and small-scale excavation projects. Their compact size allows them to navigate tight areas that larger machines cannot reach. On the other hand, small excavators, with their increased weight and power, are better suited for medium-scale construction projects, utility work, and situations where a bit more muscle is needed without sacrificing too much maneuverability.

Evaluating Performance and Efficiency

Performance and efficiency are critical factors when choosing between mini and small excavators. Mini excavators excel in scenarios where precision and delicate handling are required. Their smaller engines, typically ranging from 10 to 40 horsepower, are optimized for fuel efficiency, reducing operational costs over time. These machines are ideal for tasks such as trenching for irrigation systems, digging footings for small buildings, and performing light demolition work.

Small excavators, with engine capacities generally between 40 to 70 horsepower, offer more power and digging force. This makes them suitable for more demanding tasks, such as digging larger trenches, handling heavier materials, and working on larger construction sites. While they consume more fuel than mini excavators, their increased efficiency in handling tougher jobs can offset the higher operational costs.

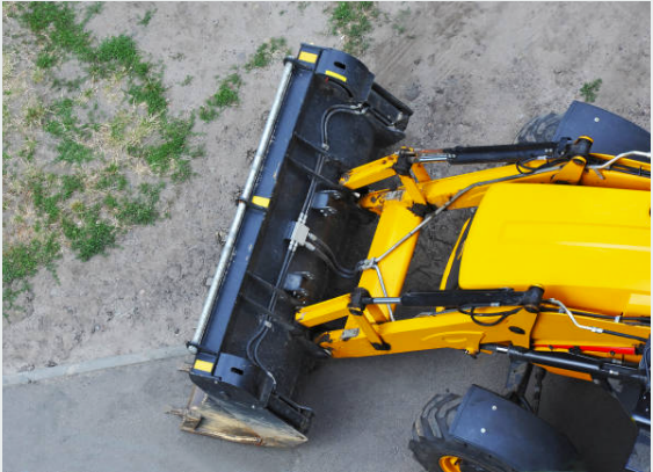

Hydraulic systems in both types of excavators are designed to enhance their performance. Mini excavators often feature advanced hydraulics that allow for smooth and precise movements, crucial for working in confined spaces. Small excavators, while also featuring sophisticated hydraulic systems, focus more on power and efficiency, enabling them to perform robust tasks with ease.

Cost Considerations and Budgeting: Maximizing Value in Second-hand Excavator Investments

Understanding Initial Costs vs. Total Cost of Ownership

At first glance, the initial cost of purchasing a second-hand excavator may seem like the most significant expense. However, savvy buyers recognize that the total cost of ownership encompasses a broader spectrum of expenses over the equipment’s lifespan. Beyond the purchase price, factors such as fuel consumption, maintenance and repair costs, depreciation, and resale value contribute significantly to the total cost of ownership. By taking a holistic view of expenses, buyers can make informed decisions that align with their long-term financial objectives.

Evaluating Performance and Reliability

While upfront costs are a crucial consideration, they should not overshadow the importance of performance and reliability. Second-hand excavators from reputable brands often retain their operational efficiency and durability, providing reliable performance despite being pre-owned. By prioritizing performance and reliability alongside cost considerations, buyers can ensure that their investment delivers the desired outcomes without compromising on quality or productivity.

Leveraging Financing and Leasing Options

For buyers operating within constrained budgets, leveraging financing and leasing options can provide valuable flexibility. Financing arrangements allow buyers to spread the cost of purchasing a second-hand excavator over time, easing the immediate financial burden. Similarly, leasing agreements offer the advantage of predictable monthly payments, enabling businesses to access the equipment they need without making a substantial upfront investment. By exploring financing and leasing options, buyers can optimize their budget allocation while acquiring the necessary equipment to support their operations.

Conducting Thorough Inspections and Assessments

Mitigating financial risks associated with second-hand equipment purchases requires thorough inspections and assessments. Buyers should engage qualified technicians to evaluate the condition of the excavator, identifying any potential issues or maintenance needs. By conducting comprehensive inspections, buyers can make informed decisions regarding the suitability of the equipment for their intended applications and anticipate any additional expenses related to refurbishment or repairs. Prioritizing due diligence during the purchasing process minimizes the likelihood of unforeseen costs arising post-acquisition.

Factoring in Operational Efficiency and Productivity

Ultimately, the value derived from a second-hand excavator investment extends beyond financial considerations to encompass operational efficiency and productivity gains. A well-maintained and reliable excavator can significantly enhance construction project timelines, reducing downtime and increasing overall productivity. By factoring in the operational benefits of investing in high-quality second-hand equipment, buyers can justify their expenditure based on the tangible improvements in project outcomes and operational performance.

Suitability for Various Construction Tasks

The suitability of mini and small excavators for various construction tasks largely depends on the specific requirements of the project. Mini excavators are ideal for:

- Residential Construction: Their compact size and precision make them perfect for digging foundations, installing utilities, and landscaping in residential areas.

- Urban Environments: In densely populated areas where space is limited, mini excavators can navigate narrow streets and operate efficiently without causing significant disruptions.

- Light Demolition: Tasks such as removing small structures, concrete driveways, and sidewalks can be effectively handled by mini excavators.

- Landscaping: Their ability to perform delicate tasks such as planting trees, creating garden beds, and installing irrigation systems makes them valuable in landscaping projects.

Small excavators, on the other hand, are better suited for:

- Commercial Construction: Their additional power and reach make them suitable for larger commercial projects, including digging trenches for utility lines and preparing foundations for larger buildings.

- Utility Work: Small excavators can efficiently handle the installation and maintenance of water, sewer, and gas lines, often requiring deeper and wider trenches.

- Agricultural Applications: Tasks such as digging irrigation ditches, clearing land, and handling farm infrastructure projects can benefit from the capabilities of small excavators.

- Medium-Scale Excavation: For projects that require more power than what mini excavators can provide but do not justify the use of larger machines, small excavators are the perfect fit.

Maintenance and Operational Ease

Proper maintenance is crucial for ensuring the longevity and efficiency of any excavator. Both mini and small excavators are designed with maintenance in mind, but there are differences in their maintenance requirements.

Mini excavators generally require less maintenance due to their simpler and more compact design. Regular checks and maintenance tasks include inspecting hydraulic systems, engine components, and track systems. Because they are often used for lighter tasks, wear and tear are typically less severe, resulting in fewer repairs and lower maintenance costs.

Small excavators, while still designed for ease of maintenance, have more complex systems due to their increased power and capabilities. Regular maintenance tasks include checking the hydraulic fluid levels, inspecting and replacing filters, and monitoring the engine and cooling systems. Given their use in more demanding tasks, small excavators may experience more wear and tear, necessitating more frequent and potentially more costly maintenance.

Operational ease is another important factor to consider. Mini excavators are known for their user-friendly controls and straightforward operation, making them accessible even to less experienced operators. Their smaller size also means that they can be transported easily between job sites using standard trailers, adding to their convenience.

Small excavators, while also designed to be user-friendly, may require more training and experience to operate effectively due to their larger size and additional features. Transporting small excavators requires larger trailers and more robust towing vehicles, which can add to logistical considerations.

For second-hand machines, thorough inspections and proper refurbishment are key to maintaining operational efficiency. At Holight Group, we ensure that all our second-hand excavators undergo rigorous checks and necessary refurbishments to meet industry standards and provide reliable performance.

Conclusion

Choosing between a mini and small excavator depends on a thorough understanding of the specific needs and constraints of your projects. Mini excavators offer unmatched precision, maneuverability, and cost-effectiveness for small-scale and residential tasks. Small excavators, with their increased power and versatility, are better suited for medium-scale projects and more demanding applications.

Both types of excavators have their unique advantages and can significantly enhance the efficiency and productivity of construction projects when chosen appropriately. By carefully evaluating factors such as performance, cost, suitability for tasks, and maintenance needs, you can make an informed decision that aligns with your operational goals and budget constraints.

Purchasing second-hand branded excavators from reputable sellers like Holight Group can offer substantial savings without compromising on quality and reliability. Our commitment to providing high-quality, pre-owned construction equipment ensures that you receive the best value for your investment.

At Holight Group, we are dedicated to helping you find the perfect excavator for your needs. Whether you need a mini excavator for precise landscaping work or a small excavator for robust commercial projects, our team is here to assist you in finding the ideal solution. Visit our website at holightgroup.com for more information and to explore our range of second-hand branded excavators and other construction equipment.