Excavators have come a long way since their inception, evolving to meet the diverse needs of the construction industry. From long-reach to wheel excavators, technological advancements have significantly enhanced their capabilities and efficiency. In this blog, we will explore the evolution of excavators, focusing on key developments and innovations.

The Rise of Long-reach Excavators: Extending Capabilities

Long-reach excavators represent a significant leap in excavation technology, designed to address the limitations of standard excavators by providing extended reach and enhanced versatility. These machines are characterized by their long booms and arms, which allow them to reach farther distances and dig deeper than traditional models. This capability makes long-reach excavators indispensable for a variety of specialized tasks, such as dredging, deep excavation, and demolition work.

One of the primary advantages of long-reach excavators is their ability to operate efficiently in hard-to-reach areas. For instance, when working on riverbanks, marshlands, or steep slopes, these machines can perform tasks that would be challenging or impossible for conventional excavators. The extended reach of the boom and arm allows operators to work from a safe distance, minimizing the risk of accidents and enhancing overall safety on the job site. This is particularly important in environments where stability and accessibility are major concerns.

In addition to their safety benefits, long-reach excavators also contribute to increased productivity. The extended reach reduces the need for repositioning the machine frequently, which saves time and enhances operational efficiency. For example, in dredging operations, a long-reach excavator can cover a larger area without needing to be moved as often, resulting in faster completion of the project. Similarly, in demolition work, the ability to reach high structures from a distance allows for more controlled and precise dismantling, reducing the risk of damage to surrounding areas.

Long-reach excavators are also highly versatile, capable of handling a wide range of attachments that expand their functionality. From hydraulic breakers and grapples to clamshell buckets and shears, these machines can be equipped with various tools to perform different tasks. This adaptability makes them suitable for a broad spectrum of projects, including material handling, slope stabilization, and underwater construction. The ability to switch between attachments quickly and easily further enhances their utility on diverse job sites.

The design of long-reach excavators has evolved to include features that enhance their performance and operator comfort. Advanced hydraulic systems provide smooth and precise control, allowing operators to perform intricate tasks with ease. Modern models often come with ergonomic cabs equipped with climate control, adjustable seats, and user-friendly interfaces, ensuring a comfortable and efficient working environment. Additionally, the use of durable materials and robust construction techniques ensures that these machines can withstand the rigors of demanding job sites.

Environmental considerations have also played a role in the development of long-reach excavators. Many manufacturers are incorporating eco-friendly technologies, such as low-emission engines and energy-efficient hydraulic systems, to reduce the environmental impact of their machines. These advancements not only help in complying with stringent regulatory standards but also contribute to the sustainability of construction practices.

Efficiency and Versatility: The Advent of Mini Excavators

Mini excavators have revolutionized the construction industry with their compact size, impressive power, and exceptional maneuverability. These small yet mighty machines are perfect for projects in confined spaces, such as urban construction sites, landscaping, and utility work. Despite their smaller footprint, mini excavators boast substantial digging and lifting capabilities, making them indispensable for a wide range of tasks.

One of the standout features of mini excavators is their ability to operate in tight spaces where larger machines cannot fit. This makes them ideal for residential projects, indoor demolitions, and trenching in narrow areas. Their compact size allows them to navigate through gates, doorways, and between structures with ease, significantly reducing the need for manual labor in areas with restricted access. This advantage not only enhances productivity but also minimizes disruption in densely populated or sensitive environments.

The lightweight nature of mini excavators is another significant benefit. Because they weigh less than their larger counterparts, they exert less ground pressure, which reduces the risk of damaging surfaces such as lawns, sidewalks, and driveways. This makes mini excavators particularly suitable for landscaping projects and work on finished surfaces. Additionally, their reduced weight makes them easier to transport between job sites, further enhancing their efficiency and versatility.

Mini excavators are also known for their advanced hydraulic systems, which provide smooth and precise control. This technology allows operators to perform delicate tasks with a high degree of accuracy, such as grading, leveling, and digging around existing structures. The hydraulic systems also contribute to faster cycle times, increasing overall productivity on the job site. Furthermore, many mini excavators come equipped with quick couplers, enabling rapid attachment changes and further enhancing their versatility.

The ability to switch between various attachments is a key feature of mini excavators. These machines can be outfitted with a wide range of tools, including buckets, augers, breakers, and grapples, allowing them to handle multiple tasks with ease. This adaptability makes mini excavators suitable for a broad spectrum of applications, from digging foundations and installing utilities to demolishing small structures and performing landscaping work. The ease of changing attachments quickly also means that a single machine can be used for various stages of a project, reducing the need for additional equipment and cutting costs.

Operator comfort and safety are paramount in the design of modern mini excavators. Many models feature ergonomic cabs with adjustable seats, climate control, and user-friendly controls, ensuring that operators can work efficiently and comfortably for extended periods. Safety features such as rollover protective structures (ROPS) and falling object protective structures (FOPS) are also standard, providing additional protection in hazardous environments.

Technological advancements have further enhanced the capabilities of mini excavators. Some models now come with advanced telematics systems that provide real-time data on machine performance, location, and maintenance needs. This information allows operators and fleet managers to monitor the health of the equipment, schedule timely maintenance, and optimize utilization, thereby reducing downtime and operational costs.

Environmental considerations are increasingly important in the construction industry, and mini excavators are no exception. Many manufacturers are incorporating eco-friendly technologies into their machines, such as low-emission engines and energy-efficient hydraulic systems. These advancements help reduce the environmental impact of construction activities and ensure compliance with stringent emissions regulations. The compact size and reduced fuel consumption of mini excavators also contribute to lower overall carbon footprints.

In conclusion, the advent of mini excavators has brought about a paradigm shift in the construction industry. Their compact size, exceptional maneuverability, and impressive power make them ideal for a wide range of applications, particularly in confined and sensitive areas. With continuous advancements in technology and design, mini excavators are set to remain a crucial asset for construction professionals, offering unparalleled efficiency and versatility on the job site.

Hydraulic Innovations: Transforming Excavator Performance

Hydraulic systems have revolutionized the excavator industry, transforming the performance and capabilities of these essential machines. By using fluid power to operate their boom, arm, and bucket, hydraulic excavators offer greater precision, power, and control compared to their mechanical predecessors. This technology has significantly enhanced the efficiency and versatility of excavators, making them more capable of tackling a wide range of tasks.

One of the key advantages of hydraulic excavators is their superior control and precision. Hydraulic systems allow for smooth and fine movements, enabling operators to perform delicate tasks such as grading, trenching, and lifting with high accuracy. This precision is crucial in projects that require detailed work, such as landscaping, utility installation, and demolition in confined spaces. Renowned brands like Caterpillar, Komatsu, and Hitachi have developed advanced hydraulic systems that provide operators with unparalleled control and responsiveness.

In addition to precision, hydraulic systems deliver substantial power, enhancing the digging and lifting capabilities of excavators. The ability to generate high levels of force enables hydraulic excavators to handle tough materials and challenging conditions with ease. For example, in heavy-duty applications like quarrying and mining, hydraulic excavators from brands like Volvo and Liebherr can efficiently break through hard rock and handle large volumes of material. This increased power also translates to faster cycle times, boosting productivity on job sites.

Hydraulic excavators are also highly versatile, thanks to their compatibility with various attachments. By simply swapping out the bucket for a hydraulic hammer, grapple, or auger, operators can quickly adapt the machine to different tasks. This versatility reduces the need for multiple machines, saving time and costs. Leading manufacturers such as JCB and Doosan offer a wide range of hydraulic attachments that enhance the functionality of their excavators, making them suitable for diverse applications from construction to forestry.

Another significant benefit of hydraulic systems is their contribution to operator comfort and safety. Modern hydraulic excavators are designed with ergonomic cabs that feature adjustable seats, intuitive controls, and climate control systems, ensuring a comfortable working environment. Safety features, such as boom and arm holding valves, prevent unintended movements and enhance stability, reducing the risk of accidents. Brands like Kubota and Hyundai incorporate these safety and comfort features into their hydraulic excavators, prioritizing operator well-being.

Technological advancements in hydraulic systems continue to drive innovation in the excavator industry. For instance, some modern hydraulic excavators are equipped with intelligent control systems that optimize hydraulic flow and pressure based on the task at hand. These smart systems, developed by companies like Komatsu and Caterpillar, improve efficiency and reduce fuel consumption, contributing to lower operational costs and environmental impact.

Environmental considerations have also spurred the development of eco-friendly hydraulic technologies. Low-emission engines, energy-efficient hydraulic pumps, and biodegradable hydraulic fluids are now standard features in many hydraulic excavators. These advancements help reduce the carbon footprint of construction activities and comply with stringent emissions regulations. Manufacturers like Volvo and Hitachi are at the forefront of incorporating sustainable technologies into their hydraulic excavators, demonstrating a commitment to environmental responsibility.

From Tracks to Wheels: The Development of Wheel Excavators

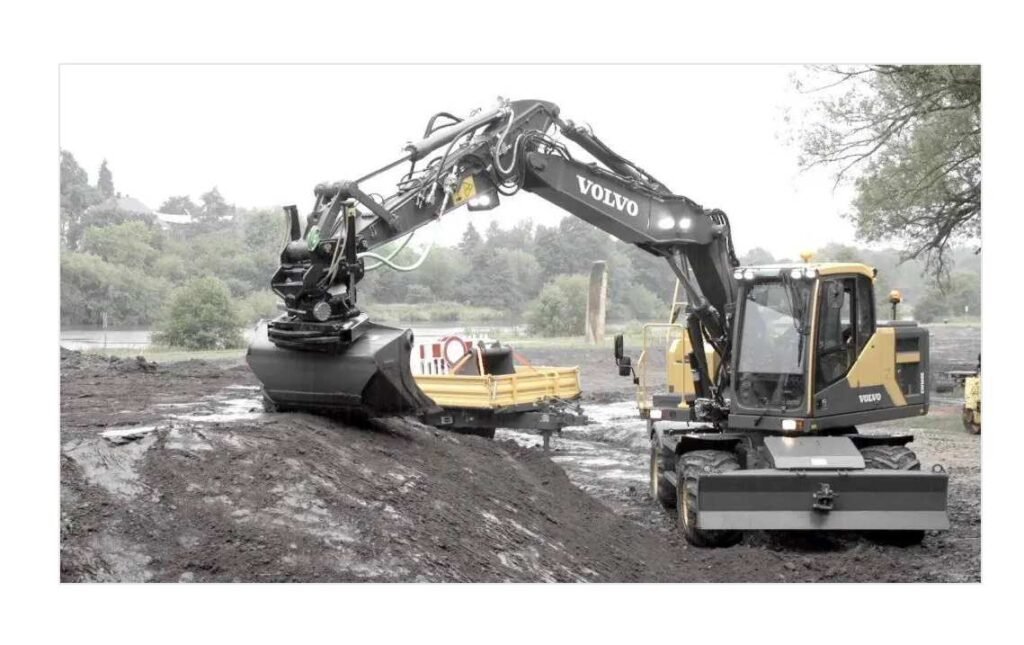

The advent of wheel excavators has introduced a new level of mobility and flexibility to the construction industry. Unlike traditional track excavators, wheel excavators are equipped with wheels, allowing them to travel quickly and easily on paved surfaces. This makes them ideal for urban projects, road construction, and tasks that require frequent movement between sites. The development of wheel excavators has been driven by the need for machines that can combine the power and versatility of tracked models with enhanced mobility.

One of the key advantages of wheel excavators is their ability to drive on roads without causing damage, unlike track excavators which can damage pavement. This reduces the need for additional transport equipment, saving time and money. Moreover, wheel excavators are designed to be versatile, with the capability to switch between different attachments quickly, making them suitable for a variety of applications. Leading brands like Caterpillar, Liebherr, and Hitachi have been at the forefront of developing wheel excavators, incorporating advanced technologies and features to enhance their performance and versatility.

Wheel excavators are particularly beneficial in urban environments where maneuverability and speed are essential. Their ability to move swiftly between job sites without the need for a trailer or flatbed truck significantly improves efficiency. For instance, when working on municipal projects such as utility installation, road maintenance, or landscaping, the ease of relocating a wheel excavator can lead to substantial time savings. This mobility is complemented by the machines’ ability to operate on various terrains, making them suitable for both paved and unpaved surfaces.

The versatility of wheel excavators is further enhanced by their compatibility with a wide range of attachments. From digging and trenching to material handling and demolition, wheel excavators can be equipped with buckets, breakers, grapples, and more. This adaptability allows a single machine to perform multiple functions, reducing the need for additional equipment and lowering operational costs. Brands like Volvo and Komatsu offer a variety of attachments designed to maximize the utility of their wheel excavators, ensuring that they can meet the diverse needs of construction projects.

Operator comfort and safety are also prioritized in the design of modern wheel excavators. Many models feature ergonomic cabs with adjustable seats, climate control, and user-friendly controls, ensuring that operators can work efficiently and comfortably for extended periods. Safety features such as advanced braking systems, stability control, and visibility enhancements are standard in many wheel excavators from manufacturers like JCB and Hyundai, providing additional protection in demanding work environments.

Technological advancements have played a significant role in the development of wheel excavators. Modern models are equipped with state-of-the-art hydraulic systems that provide smooth and precise control, enabling operators to perform tasks with high accuracy. Intelligent control systems, developed by companies like Caterpillar and Hitachi, optimize hydraulic flow and pressure based on the task at hand, improving efficiency and reducing fuel consumption. These innovations contribute to lower operational costs and a reduced environmental impact.

Environmental considerations are increasingly important in the construction industry, and wheel excavators are no exception. Many manufacturers are incorporating eco-friendly technologies into their machines, such as low-emission engines and energy-efficient hydraulic systems. These advancements help reduce the environmental impact of construction activities and ensure compliance with stringent emissions regulations. Brands like Volvo and Komatsu are leading the way in integrating sustainable technologies into their wheel excavators, demonstrating a commitment to environmental responsibility.

Holight Group is proud to offer high-quality used wheel excavators that embody these advancements. Our machines, sourced from leading brands, are meticulously maintained and in excellent condition, providing reliable performance at a cheap price. With features like original chains and buckets, no screws of the three major parts moved, and original paint, our wheel excavators ensure durability and efficiency. Visit www.holightgroup.com to explore our selection and find the perfect machine for your construction needs.

In conclusion, the development of wheel excavators has significantly enhanced the mobility, versatility, and efficiency of construction equipment. With continuous advancements in technology and design, wheel excavators are set to remain a crucial asset for construction professionals, offering unparalleled performance and adaptability on the job site. The contributions of leading brands and the offerings from Holight Group ensure that wheel excavators are equipped to meet the demands of modern construction projects.