In the construction and mining industries, excavators are essential machines used for digging, lifting, and moving large amounts of material. Excavators come in a range of sizes, from compact mini excavators to large heavy-duty models. Each size has its own set of benefits and drawbacks, making it suitable for specific applications. Whether you’re working on urban construction, large-scale earthmoving, or mining operations, understanding the strengths and limitations of different excavator sizes can help you determine which size suits various projects best.

Compact (Mini) Excavators

Compact or mini excavators typically weigh between 1 to 6 tons and are designed for smaller, more precise tasks. These machines are highly versatile and can be used in a variety of settings, including urban areas and confined spaces.

- Pros of Compact Excavators

① Maneuverability: Due to their smaller size, compact excavators can easily navigate tight spaces and are ideal for urban projects where space is limited.

② Versatility: These machines can be equipped with a wide range of attachments, making them suitable for various tasks such as digging, grading, and demolition.

③ Lower Cost: Compact excavators are generally less expensive to purchase, operate, and maintain compared to larger models.

④ Reduced Impact: Their smaller footprint causes less damage to the worksite, which is particularly beneficial in residential areas. - Cons of Compact Excavators

① Limited Reach and Depth: Due to their size, compact excavators have a limited reach and digging depth, making them unsuitable for large-scale excavation projects.

② Lower Power: These machines have less power and lifting capacity compared to larger excavators, which can be a disadvantage for heavy-duty tasks.

③ Stability Issues: Compact excavators can be less stable on uneven or rough terrain, limiting their use in certain environments.

Mid-Sized Excavators

Mid-sized excavators typically weigh between 6 to 20 tons. These machines offer a balance between the maneuverability of compact excavators and the power of larger models, making them suitable for a wide range of projects.

- Pros of Mid-Sized Excavators

① Versatility: Mid-sized excavators can handle a variety of tasks, including digging, lifting, and material handling, making them suitable for both residential and commercial projects.

② Improved Reach and Depth: These machines offer greater reach and digging depth compared to compact models, allowing them to handle larger excavation tasks.

③ Better Stability: Mid-sized excavators are generally more stable on uneven terrain, providing a safer and more reliable option for various work environments.

④ Cost-Effective: While more expensive than compact models, mid-sized excavators still offer a good balance of performance and cost, making them a cost-effective choice for many projects. - Cons of Mid-Sized Excavators

① Higher Operating Costs: Mid-sized excavators have higher fuel consumption and maintenance costs compared to compact models.

② Limited Maneuverability: While more maneuverable than large excavators, mid-sized models can still struggle in very tight spaces or heavily congested urban areas.

③ Transport Challenges: Transporting mid-sized excavators can be more challenging and costly compared to compact models, especially if they need to be moved frequently between job sites.

Large Excavators

Large excavators weigh over 20 tons and are designed for heavy-duty tasks in large-scale construction, mining, and industrial projects. These machines offer exceptional power, reach, and capacity.

- Pros of Large Excavators

① High Power and Capacity: Large excavators have the power and capacity to handle the most demanding tasks, including heavy lifting, deep excavation, and extensive material handling.

② Extended Reach and Depth: These machines offer significant reach and digging depth, making them ideal for large-scale excavation projects.

③ Durability: Large excavators are built to withstand harsh conditions and continuous use, providing long-term reliability for demanding projects.

④ Efficiency: For large projects, the efficiency and productivity of large excavators can significantly reduce project timelines and costs. - Cons of Large Excavators

① High Costs: Large excavators are significantly more expensive to purchase, operate, and maintain compared to smaller models.

② Limited Maneuverability: Due to their size, large excavators are less maneuverable and can be challenging to operate in confined spaces or congested areas.

③ Transport and Logistics: Transporting large excavators requires specialized equipment and can be costly and logistically complex.

④ Environmental Impact: The large footprint and weight of these machines can cause substantial damage to the worksite and surrounding areas.

Choosing the Right Excavator Size for Your Project

When selecting the right excavator size for your project, consider the following factors:

① Project Scope: Assess the size and scope of your project to determine the required power, reach, and capacity.

② Site Conditions: Evaluate the site conditions, including terrain, space constraints, and accessibility.

③ Budget: Consider your budget for purchasing, operating, and maintaining the excavator.

④ Task Requirements: Identify the specific tasks the excavator will perform, such as digging, lifting, grading, or demolition.

⑤ Transport Logistics: Factor in the logistics and costs associated with transporting the excavator to and from the job site.

⑥ Urban Construction: For urban construction projects with limited space, compact excavators are ideal due to their maneuverability and reduced impact on the surroundings.

⑦ Residential Projects: Mid-sized excavators are well-suited for residential projects that require a balance of power and maneuverability.

⑧ Commercial Construction: For larger commercial construction projects, mid-sized to large excavators provide the necessary power and capacity to handle more extensive tasks.

⑨ Mining and Industrial Projects: Large excavators are essential for mining and industrial projects where heavy-duty performance, reach, and capacity are critical.

Maintenance Tips for Different Excavator Sizes

To ensure optimal performance and longevity of excavators, it is essential to conduct thorough inspections and maintenance tailored to the size of the machine.

- For all excavators:

① Regular Inspections: Conduct thorough inspections to identify and address potential issues before they become major problems.

② Lubrication: Ensure all moving parts are properly lubricated to reduce friction and wear.

③ Filter Changes: Replace hydraulic and fuel filters regularly to maintain system cleanliness and efficiency.

④ Fluid Levels: Check and maintain appropriate fluid levels, including engine oil, coolant, and hydraulic fluid.

⑤ Track and Tire Care: Inspect tracks and tires for wear and damage, and replace them as necessary to ensure safe operation. - Specific Suggestions Based on Excavator Size:

① Compact Excavators: Given their smaller size, maintenance tasks can be more straightforward and less time-consuming. Regular checks on hydraulic systems, electrical components, and the undercarriage can help extend the life of the machine.

② Mid-Sized Excavators: These machines require a balance of routine checks and preventive maintenance. Focus on the engine, hydraulic systems, and wear parts such as the bucket and teeth. Regular cleaning and inspections can prevent costly repairs.

③ Large Excavators: For these heavy-duty machines, a comprehensive maintenance plan is essential. Regularly monitor the engine, hydraulics, and structural components. Given their intensive use, scheduling downtime for maintenance is crucial to avoid unexpected breakdowns.

Environmental Considerations

① Compact Excavators: These machines have a smaller environmental footprint. They cause less soil compaction and are suitable for projects in sensitive areas where minimizing disruption is critical.

② Mid-Sized Excavators: While offering a balance between power and size, mid-sized excavators have a moderate impact on the environment. Proper operation and maintenance can mitigate adverse effects.

③ Large Excavators: These machines can significantly impact the environment due to their size and power. They cause more soil disturbance and may require additional measures to manage environmental impact, such as erosion control and site restoration.

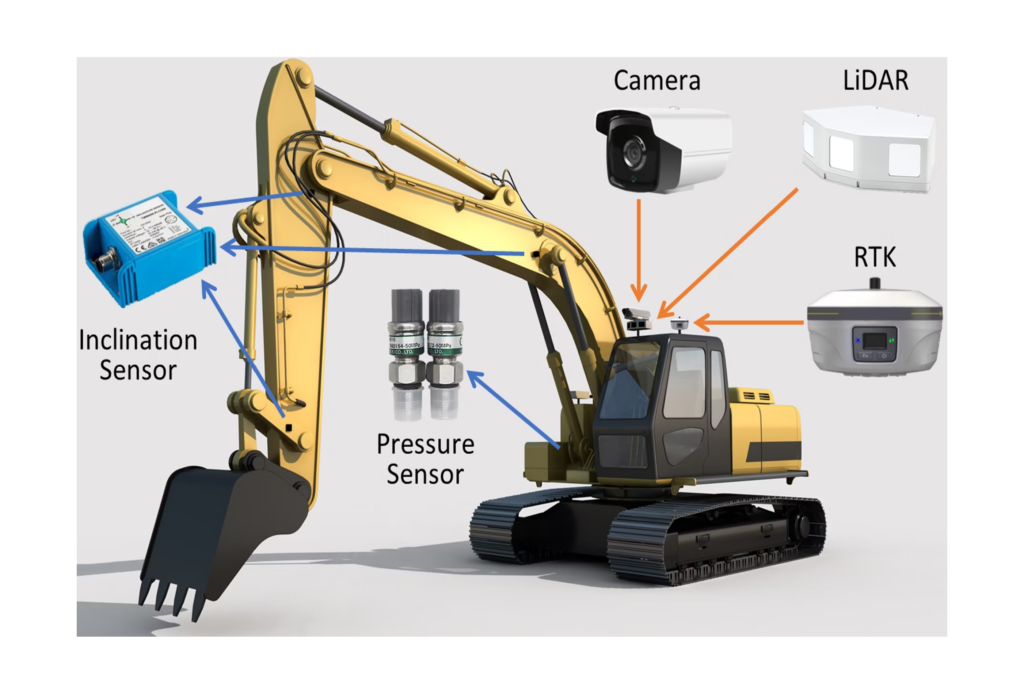

Technological Advancements in Excavators

Technology enhances excavator efficiency by optimizing performance and reducing fuel consumption. Automation and telematics improve safety with real-time alerts and less manual intervention. Electric and hybrid systems cut emissions, promoting sustainability. Telematics and data analytics provide insights for better decision-making.

① Telematics: Modern excavators are equipped with telematics systems that provide real-time data on machine performance, location, and fuel consumption. This technology helps in optimizing operations and maintenance.

② Automation and Autonomy: Advances in automation are leading to semi-autonomous and fully autonomous excavators. These machines can perform tasks with minimal human intervention, increasing efficiency and safety.

③ Electric Excavators: Electric-powered excavators are becoming more common, offering a cleaner alternative to diesel engines. These machines are ideal for urban projects and indoor use where emissions are a concern.

④ Hybrid Systems: Hybrid excavators combine diesel engines with electric motors to improve fuel efficiency and reduce emissions. These systems are designed to provide the power needed for heavy-duty tasks while minimizing environmental impact.

Cost Analysis of Excavator Sizes

- Compact Excavators

Generally the lowest among the three sizes due to its smaller size and lower capacity. Compact excavators typically consume less fuel per hour compared to larger models, resulting in lower fuel costs. Generally less complex and cheaper to maintain due to simpler components. Ideal for smaller projects with limited budgets where maneuverability and lower operating costs are prioritized. Offers the most cost-effective solution for projects that do not require extensive digging depth or lifting capacity. - Mid-Sized Excavators

Moderate compared to compact and large excavators, balancing cost and performance. More fuel-efficient than large excavators but generally higher than compact models. Maintenance costs are moderate, balancing between compact and large excavators. Suitable for medium-scale projects that require more power and reach than compact excavators but do not necessitate the capacity of larger machines. Offers a balance between initial investment and operational costs, making it suitable for a wide range of construction and excavation tasks. - Large Excavators

Highest among the three categories due to size, capacity, and advanced features. Consumes the most fuel per hour due to greater power and capacity. Maintenance costs are higher due to the complexity and size of components. Essential for large-scale projects that require heavy-duty digging, lifting, and reach capabilities. While initial and operating costs are higher, large excavators offer efficiency in handling extensive and demanding tasks that smaller models cannot accomplish effectively.

Safety Features and Safe Operation of Modern Excavators

Modern excavators feature ergonomic cab designs with enhanced visibility, reducing operator fatigue and improving safety. These systems include features like automatic stability control, overload warning systems, and automated digging functions. Real-time alerts for potential hazards, such as proximity sensors and collision avoidance systems, enhance safety on the job site. Advanced excavators are equipped with emergency shut-off systems and fire suppression systems to handle critical situations.

Ensure operators are properly trained and certified to handle the specific size and type of excavator. Conduct regular safety inspections to identify and address potential hazards. Maintain clear communication between operators and ground personnel to avoid accidents. Operators and ground personnel should always wear appropriate PPE, including helmets, gloves, and high-visibility clothing. Properly manage the job site by setting up barriers, signage, and clear pathways to prevent accidents.

Conclusion

Choosing the right excavator size for your project is a critical decision that impacts efficiency, safety, and cost. By understanding the pros and cons of different excavator sizes and considering factors such as project scope, site conditions, budget, and specific task requirements, you can make an informed choice that ensures the success of your project. Whether you need the maneuverability of a compact excavator, the versatility of a mid-sized model, or the power of a large excavator, selecting the appropriate machine will help you achieve your goals effectively and efficiently.

By following this guide and considering the detailed information provided, you can confidently choose the best excavator size for your specific needs and ensure that your projects are completed to the highest standards.